Technology

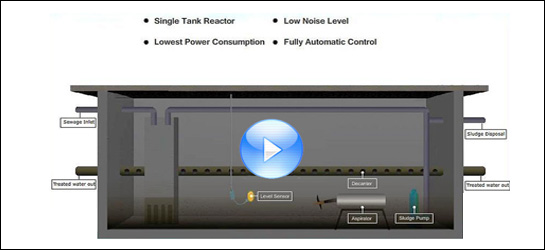

Grewa R

Filling : The ‘Quick Fill’ Mode, a batch tank is used to accumulate incoming sewage. Controlling the incoming waste water helps in optimising F/M ratios which in turn enhances the bacterial growth for better settling. The batch tank acts as an equilisation tank allowing the process to handle peak loads efficiently.

Mixing/Reaction : The Batch is then pumped into a reaction chamber in the shortest possible time creating a ‘Feed and Starve Mode’ for the bacteria in the system.

Aeration/Mixing : BOD and Ammonium Nitrogen levels are controllers. Timing for aeration is dependent on the preceding parameters. Of aeration and resultant sludge determines treatment level.

Settling : Built-in sludge management system controlled by means of specially developed process logic automated sludge control and storage systems. Cycle time adjustments helps in achieving more efficient nutrient removal and enables creation of clear water, treated effluent above the settled sludge. This effectively handles sludge Inventory.

Decanting/Drainage : Sequential methodology for sludge digestion and thickening reduces frequent operator intervention. Treated effluent is removed through the specially designed decanter, without agitating the sludge. Adjustments to MLSS concentration and MRT help in controlling the treated waste water quality.

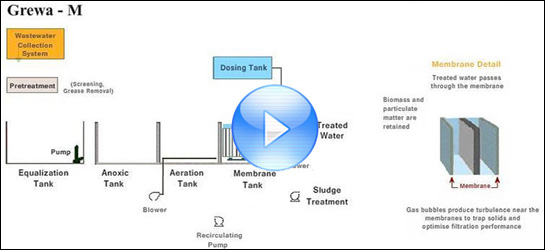

Grewa M

The technology of using membrane separation method of activated sludge, commonly referred to as "Membrane Bio-Reactor" (MBR), is the combination of activated sludge treatment together with a separation of the biological sludge by micro or ultra-filtration membranes with pore size of typically 10 nm to 0.5µm to produce particulate-free effluent. Use of Micro or Ultra Filtration replaces final clarifiers used in conventional activated sludge treatment which achieve solid separation by gravity only. Physical barrier imposed by the membrane system method provides complete disinfection of the treated effluent. It also enables operation at higher sludge concentrations (typically up to 20 gm/Ltr as compared to an earlier max. 6 gm/Ltr with conventional systems). Therefore this method reduces the footprint of the entire plant besides also reducing sludge production.

|